TECHNICAL OFFICE

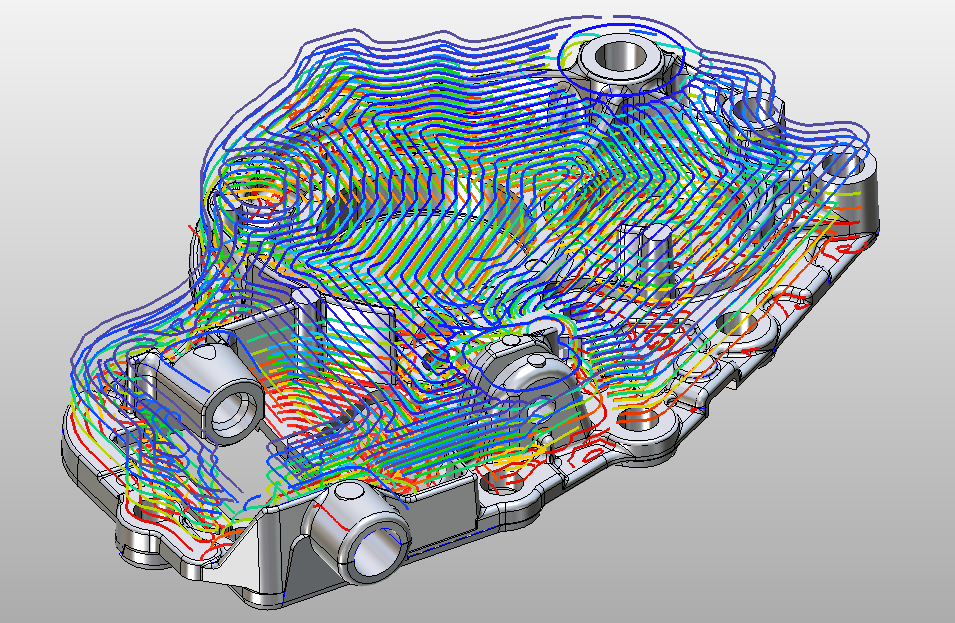

Evotek has various CAD stations for the design and development of mathematical dimensions:

- Design Software: Zw3D, CATIA for advanced design and modeling.

- Bending Process Simulation Software: Amada Product Designer

- Forming Process Simulation Software: STAMPACK Xpress: Used for advanced simulations of stamping and forming processes.

Utilizes a barcode management system to maximize productivity and order management.

Additionally, it has an internal data center equipped with servers for the protection and secure storage of data.

3D PRINTING: Stratasys F770 and Fortus 450mc

Evotek utilizes the Stratasys F770, one of the first industrial 3D printing machines in Italy.

This technology offers an unprecedented build volume (1000 x 610 x 610 mm), ideal for creating prototypes and large-scale components with precision and reliability.

The F770 uses high-performance thermoplastics like ASA and ABS-M30, perfect for automotive applications.

Thanks to its ability to work with UV-resistant materials like ASA, Evotek provides durable and resistant parts.

With the Stratasys F770, Evotek simplifies the production process in the automotive sector by reducing the time and costs associated with traditional production. It offers dedicated services for rapid prototyping and large-scale additive manufacturing, positioning itself as a strategic partner for innovative automotive companies.

The Stratasys Fortus 450mc is an industrial 3D printer that uses FDM technology to produce functional prototypes and production parts with advanced thermoplastics like carbon fiber and PEI. The maximum build area is 406 x 356 x 406 mm, ideal for large parts.

Among its key features are four material cartridge bays and the ability to work with a wide range of materials. These materials offer high mechanical properties and chemical and thermal resistance.

The benefits include reducing production time and costs, the ability to create functional prototypes and lightweight yet robust tooling, accelerating product development.