TIG, MIG, LASER WELDING

Evotek performs TIG and MIG WELDING on all types of:

- ALUMINUM

- IRON

- STAINLESS STEEL

- TITANIUM

- INCONEL

Evotek also performs LASER welding of small parts.

The quality of the processes is guaranteed by the most important global certifications in welding.

- TIG Miller Dynasty 200 & 350: Ideal for precise welding on thin and thick metals.

- MIG Miller Migmatic 300DX & XMS44: Suitable for welding on steel, stainless steel and aluminum, with high arc stability.

- Selco Genesis 350 GSM: Advanced welding machine with inverter technology for high efficiency and performance.

- Fronius TPS 320i: MIG/MAG welding machine, with intelligent arc control.

LASER CUTTING AND MARKING

Laser Cutting with LASER AMADA ENSIS 3015 AJ Fiber Laser Rotary Index

- Maximum Cutting Dimensions: 3000 mm x 1500 mm

- Maximum Material Thickness:

- Mild Steel: Up to 25 mm

- Stainless Steel: Up to 15 mm

- Aluminum: Up to 12 mm

- Brass: Up to 8 mm

- Copper: Up to 6 mm

- Features: High precision, high cutting speed, ideal for complex machining on various metals.

Tube Cutting:

- Materials: Same as 2D cutting

- Diameters: 20 to 170 mm

- Square Sections: 20x20 to 170x170 mm

- Thicknesses: Same as 2D

Laser Marking with LASIT Fiberfly Marker

Engraves metals and thin materials with high precision, using fiber laser technology.

CNC MILLING

3-Axis Machining Center DMG MORI CMX 1100 V

- Working Dimensions: X Travel 1100 mm, Y Travel 550 mm, Z Travel 510 mm

- Features: High precision, powerful spindle, ideal for complex machining on metals.

3-Axis Machining Center MAZAK VTC 760 C

- Working Dimensions: X Travel 1740 mm, Y Travel 760 mm, Z Travel 660 mm

- Features: Reliability and precision for high productivity machining.

4-Axis Machining Center MAZAK VTC-820/20

- Working Dimensions: X Travel 2000 mm, Y Travel 820 mm, Z Travel 720 mm

- Features: Versatile and precise, for machining with simultaneous movement on 4 axes.

BENDING

Electric Bending Machine Trumpf Trubend 7036

- Bending Capacity: Up to 3 m in length, 36 tons of force.

- Features: High precision and repeatability in bending thin metals.

Electric Bending Machine Trumpf Trubend 5130

- Bending Capacity: Up to 1 m in length, 130 tons of force.

- Features: High-quality bending with advanced CNC control.

Bending Machine AMADA HG 100-3 ATC

- Bending Capacity: Up to 3 m, with 100 tons of force.

- Features: Precise bending on complex materials, with automatic tool change.

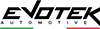

TUBE BENDING

Uncompromising Industrial Precision.

Our advanced CNC tube bending machine transforms tubes up to 80mm into complex geometries with absolute reliability. Equipped with integrated 3D software, it analyzes feasibility, collisions, and bending parameters in real-time, ensuring the first piece is correct from the start.

Ideal for series production or unique pieces, it reduces setup times by 70% and optimizes costs through automated cycles, a robotic loader, and intelligent unloading.

Extreme versatility, certified safety, and scalable investment: the turnkey solution for those who demand maximum efficiency without sacrificing quality.

MOULDING

Hydraulic and Hydrostatic Presses:

Mossini Press RO/AC200:

- Capacity: 200 tons.

Galfer Hydraulic Press 4CVP100:

- Capacity: 100 tons.

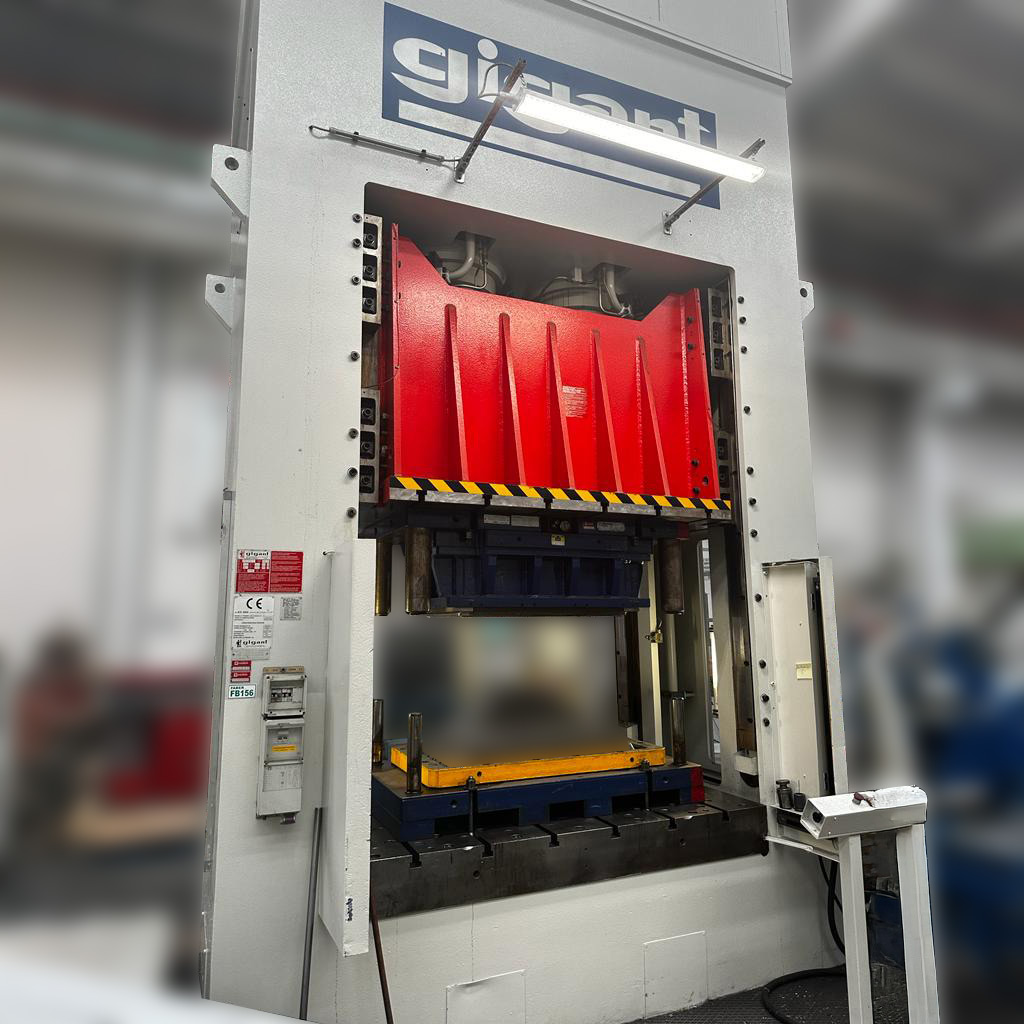

Gigant Hydraulic Press G/2 – 315/2:

- Working Area: Approximately 2000 x 1500 mm.

- Capacity: 315 tons.

Gigant Hydraulic Press G2-500/2:

- Working Area: Approximately 2000 x 1500 mm.

- Capacity: 500 tons.

SICMI Hydrostatic Press Model PST150:

- Capacity: 150 tons.

ASSEMBLY

- Boxes and Work Surfaces: Custom fabrication of large work surfaces for the assembly of components of various sizes, such as frames, shells, or smaller components.

- Custom Jigs: Creation of jigs for complex assemblies, ensuring precision at every stage.